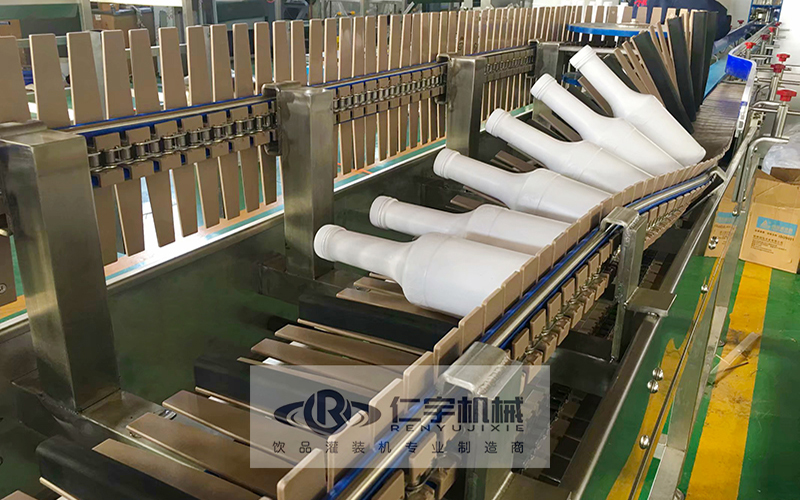

PET bottle three in one machine integrates washing, filling and capping. It is developed on the basis of technology and according to the requirements of the filling process of tea, fruit juice and other drinks. The filling temperature is generally about 82-85 ℃.

Main features:

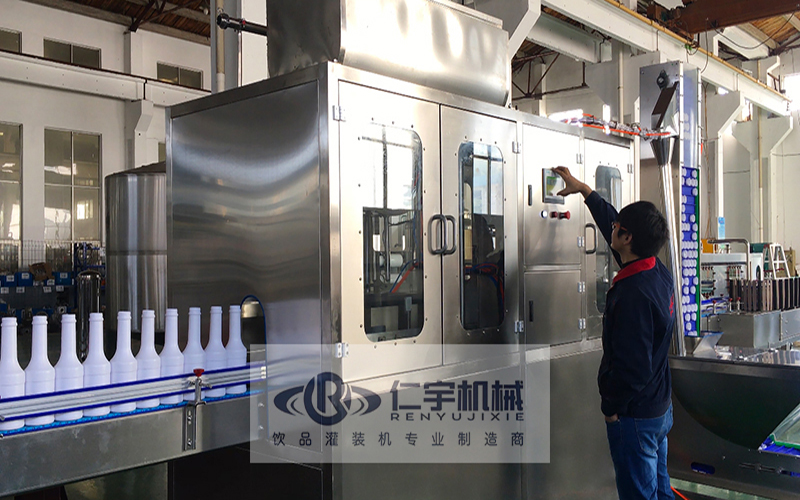

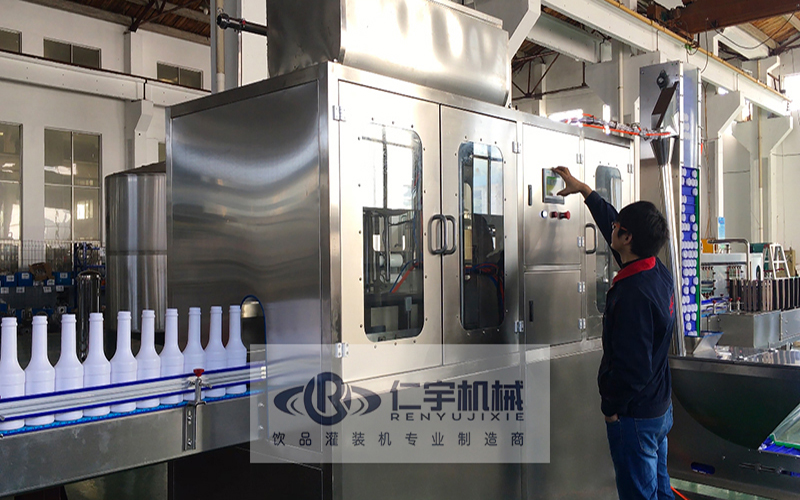

(1) The machine has compact structure, complete control system, convenient operation and high degree of automation;

(2) To change the bottle shape, just replace some star wheels of the screw cap and the arc guide plate;

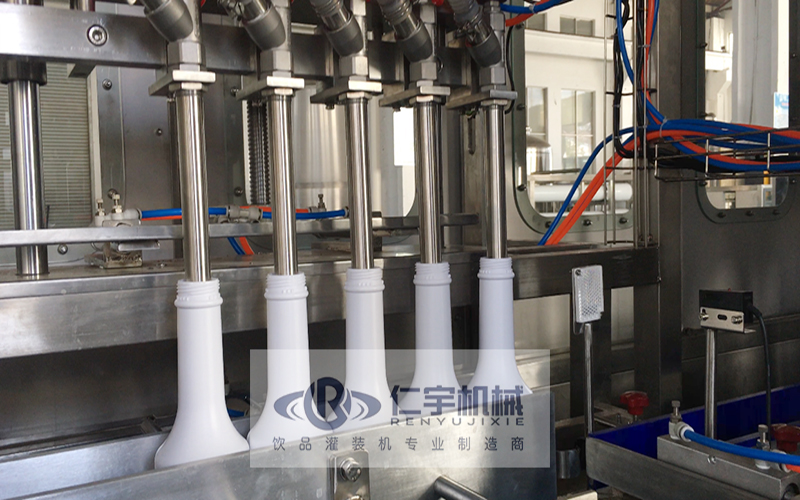

(3) The parts in contact with materials are made of stainless steel, which reduces the dead angle of process and is easy to clean;

(4) High speed filling valve is adopted to ensure accurate liquid level and reduce liquid loss. Filling process requirements;

(5) . The capping head adopts a magnetic constant torque device, and the capping quality will not damage the bottle cap;

(6) The cover management system adopted has perfect automatic control and protection devices;

(7) Complete overload protection device is set to effectively protect the safety of equipment and operators;

(8) The control system has the functions of production speed control, cap missing detection, automatic stop of bottle jamming and output counting;

(9) Main electrical components are MITSUBISHI, SCHNEIDER and other products of Japan, and pneumatic components are Airtac products of Taiwan;

(10) The touch screen control adopted for the whole machine operation can realize man-machine conversation operation.