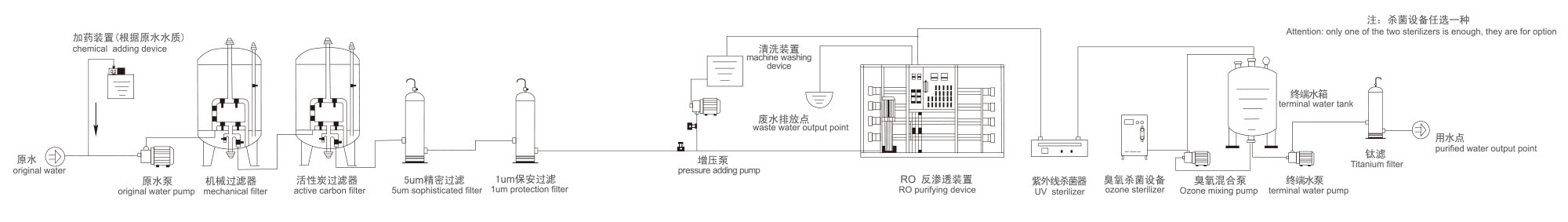

Process flow description of water treatment equipment:

The first stage pre-treatment system: quartz sand multi-media filter is adopted, which is mainly used to remove the sediment, manganese, rust, colloidal substances, mechanical impurities, suspended solids and other substances harmful to human health with particles above 20UM. The automatic filtering system adopts imported Fleck controller, which can automatically carry out a series of operations such as back flushing and forward flushing. At the same time, the equipment has a self maintenance system with low operating costs. Filter materials mainly include PPF, AC coconut carbon, etc.

The second stage pretreatment system: the activated carbon filter is used to remove the pigment, odor and a large amount of biochemical organics in the water, reduce the residual chlorine value, pesticide pollution and other pollutants harmful to human health. The automatic filtering system adopts imported Fleck controller, which can automatically carry out a series of operations such as back flushing and forward flushing.

The third stage pretreatment system: Cationic resin is used to soften the water, mainly to remove the hardness of the water. The hardness of water is mainly composed of calcium (Ca2+) and magnesium (Mg2+) ions. When the raw water containing hardness ions passes through the resin layer, Ca2+and Mg2+in the water are exchanged and adsorbed by the resin. At the same time, sodium Na+ions are released from the same mass. The water flowing out of the water softener is the softened water with the hardness ions removed. So as to effectively prevent reverse osmosis membrane scaling. The system can automatically back flush and forward flush. And it can regenerate intelligent resin to prolong the service life of the system.

The fourth stage pretreatment system: the water is further purified by using a precision filter with a diameter of 5 microns to optimize the turbidity and chromaticity of the water. Ensure water inflow requirements of RO system. The main machine system of the purified water equipment adopts reverse osmosis technology for desalination. The reverse osmosis membrane has a pore diameter of 0.0001 μ m, which can remove harmful soluble solids, bacteria, viruses, etc. The desalination rate is more than 99.6%. The purified water meeting the national standards is produced. The main machine part includes a security filter, a high-pressure pump and a reverse osmosis membrane. The security filter is the fourth stage pretreatment system above. The high-pressure pump is one of the core equipment on the main machine, Provide sufficient pressure for reverse osmosis membrane elements to overcome osmotic pressure and running resistance and meet the rated water output of the device.